Slag remover is a material used to remove impurities in molten iron or molten steel from ladle in steelmaking or casting industry. Its main components are SiO2, Al2O3 and some other chemicals. The general deslagging agent also has the function of heat preservation by covering the metal liquid.Currently we have three models of slag remover: Volcanic rock sand slag coagulant, perlite sand slag remover, and new compound slag remover.

Whatsapp:

+8618337276299Email:

sale01@tsferroalloy.com1. Slag removal and slag blocking: High-efficiency slag removal agent can be used in ladles, crucible boilers, electric furnaces, and reverberatory furnaces. Reduce sand inclusions in castings and improve quality. It has low cost, does not explode or splash, is safe and reliable, and is easy to use.

2. Insulation performance: The high-efficiency slag aggregating agent has a low thermal conductivity. The floating layer formed on the surface of the molten metal can prevent the heat conduction and radiation of the solution and become a good thermal insulation layer. This is an excellent thermal insulation covering agent for intermediate subcontracting or metal solutions that need to be stored for a long time.

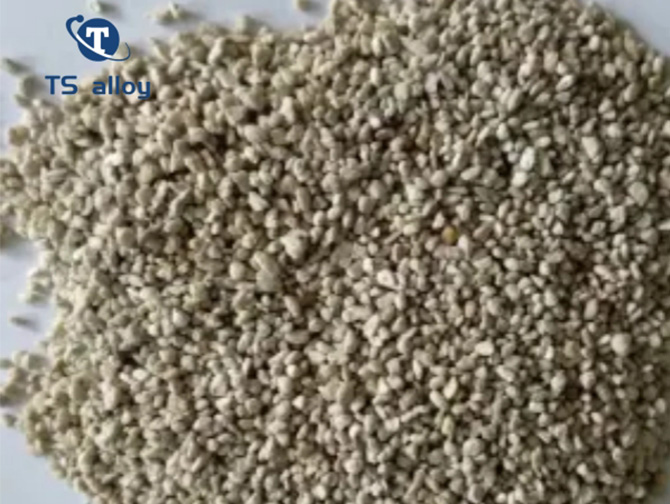

1. the appearance of the product is off-white, granular, non-toxic, tasteless.

2. It is added with less, with large expansion and small cooling.

3. the product is a composite poly-slag agent, good spreading, high temperature resistance, non-staining package, can improve the service life of the furnace lining, has a good effect of poly-slag, can effectively improve the utilisation rate of molten iron, improve the casting process yield.

4. the use of no smoke and dust, can maintain a clean workshop production environment.

The product is suitable for ductile iron, phosphor iron, box casting, carbon steel, alloy steel, high manganese steel, stainless steel, etc., in the actual casting production has achieved significant economic benefits.

Slag removal in smelting process

Slag remover is used in the metal smelting process to help remove dross from the surface of molten metal to ensure the purity and quality of the metal.

Improve metal recovery

By effectively removing dross, dross removers can improve metal recovery, reduce metal losses and lower production costs.

Improve metal flow

Dross removers can improve the flowability of molten metal, promote the filling of metal in the casting mould and reduce casting defects.

Protecting furnace lining

In the process of high temperature smelting, slag remover can reduce the erosion of dross on the furnace lining and prolong the service life of the furnace lining.

Reduce environmental pollution

The use of slag remover can reduce the generation of harmful gases and solid wastes, and reduce the impact of the smelting process on the environment.

Application in foundry industry

In the casting process, slag remover is used to remove the dross produced during the casting process, ensuring the surface finish and internal quality of the castings.

Our factory produces a variety of foundry materials to remove slag covering agent, is a substitute for the domestic foundry industry traditionally used straw ash and perlite cover the casting ladle steel water alternative products. The use of our products can make bonding ladle steel water small slag system, poly-slag ability is very strong, easy to pick up, purify steel water, prevent the waste slag with the steel water poured into the sand caused by the slag produced by the household, and the factory production of poly-slag agent, in the use of the process of spreading rapidly, uniformly, not stained packages, no pollution of dust, on the casting of the chemical composition and mechanical properties of the castings have no effect, is a solution to the poor quality of castings, low metal liquid utilisation, energy consumption is a new process. It is a new technology to solve the problem of poor quality of castings, low utilisation rate of metal liquid and high energy consumption, and it has strong slag gathering ability, which is an ideal agent for iron water purification and treatment.

|

Slag Remover Model |

Physical Properties |

||

|

Size |

Size |

Size |

|

|

Perlite Sand |

18-30 mesh |

30-50 mesh

|

50-80 mesh

|

|

Volcanic Rock |

|||

|

Compound Type |

|||

Ps: chemical compostion and size above can be optimized according to custom's requirement.

25Kg/bag, 1MT/bag or according to customer's requirements

1.100% EXW Price

2.100% irrevocable L/C at sight

3.30% advance payment, Balance against copy B/L.

Within 10 days after receiving the prepayment.

Henan Tiesheng Alloy New Material is a professinal ferroalloys manufacturer. The main products are Nodulizer,Inoculant, Ferro Silicon, Calcium Silicon, Spheroidizing Wire, Magnesium Ingot, Recarburizer, Silicon Carbide, Silicon Metal, etc.

Slag Remover is one of the ferroalloys commonly used in steel industry. Products are exported to Malaysia, the Philippines, Singapore, South Korea, Japan and Europe and the United States and other countries and regions. The quality of lc ferro chromium products is stable and the price is low. It is well received by customers.

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.