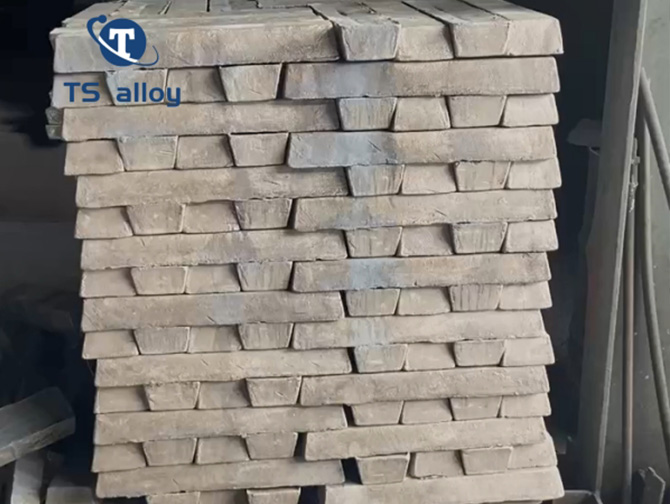

Magnesium ingot is a high-purity metal material with magnesium as the main component, usually in the form of a rectangle or cylinder.

Whatsapp:

+8618337276299Email:

sale01@tsferroalloy.com1. Chemical composition: Magnesium ingot is mainly composed of magnesium metal, with extremely high purity, usually above 99.9%, and may contain trace amounts of other metals or non-metallic impurities.

2. Physical properties: Magnesium ingot has good metallic luster and is a lightweight metal with a density of 1.74 g/cm³, a melting point of about 648.8°C, and a boiling point of about 1107°C.

3. Mechanical properties: Magnesium ingot has a high specific strength, that is, under the same strength conditions, its weight is lighter, which makes magnesium ingot very popular in the manufacture of lightweight alloys.

4. Corrosion resistance: Magnesium ingot itself has a certain degree of corrosion resistance, but it may oxidize in certain environments (such as humid environments).

5. Processing performance: Magnesium ingot can be processed into different shapes and sizes through casting, forging, extrusion and other processes to meet the needs of different applications.

6. Application fields: Magnesium ingots are widely used in aerospace, automobile manufacturing, electronics industry, metallurgy industry, chemical industry, medical equipment, sports equipment and other fields.

7. Packaging and storage: Magnesium ingots are usually packaged in iron barrels, wooden boxes or other suitable containers and stored in a dry, ventilated and moisture-proof environment to prevent oxidation and corrosion.

8. Safety measures: Since magnesium ingots are easy to burn in powder or debris state, appropriate safety measures need to be taken during handling and storage to avoid fire and high temperature.

9. Environmental protection characteristics: In the production process of magnesium ingots, some companies have adopted environmental protection technologies, such as the circular industrial chain production model, to reduce the impact on the environment.

10. Product specifications: Magnesium ingots have a variety of standard sizes and shapes, and can be customized according to the specific needs of customers.

As an important industrial raw material, the product description of magnesium ingots involves its chemical composition, physical properties, processing performance, application fields, safety and environmental protection.

Steelmaking industry

As an alloying element, silicon metal is used to increase the strength, toughness and wear resistance of steel and improve the overall properties of steel.

As a deoxidising agent, it removes oxides from steel, reduces gas inclusions and improves the quality and stability of steel.

Foundry industry

Used in the production of cast iron and cast aluminium alloy to improve the fluidity and strength of castings and reduce casting defects.

Chemical industry

Used in the production of silicon compounds such as silicates and silanes, which are widely used in the production of materials such as paints, rubber and plastics.

Electronics industry

Used in the manufacture of semiconductor materials, widely used in the production of electronic components and solar cells.

| GB/T 3499 - 2011 National Standard For Magnesium Ingots | ||||||||||||

| Designation | Chemical Composition (Mass Fraction )/% | |||||||||||

| Mg(Not less than)Mg (mln.) | lmpurities(not greater than) | |||||||||||

| Fe | Si | Ni | Cu | Al | Mn | Ti | Pb | Sn | Zn | Each of Other Impurities | ||

| Mg9999 | 99.99 | 0.002 | 0.002 | 0.0003 | 0.0003 | 0.002 | 0.002 | 0.0005 | 0.001 | 0.002 | 0.003 | — |

| Mg9998 | 99.98 | 0.002 | 0.003 | 0.0005 | 0.0005 | 0.004 | 0.002 | 0.001 | 0.001 | 0.004 | 0.004 | — |

| Mg9995A | 99.95 | 0.003 | 0.006 | 0.001 | 0.002 | 0.008 | 0.006 | — | 0.005 | 0.005 | 0.005 | 0.005 |

| Mg9995B | 99.95 | 0.005 | 0.015 | 0.001 | 0.002 | 0.015 | 0.015 | — | 0.005 | 0.005 | 0.01 | 0.01 |

| Mg9990 | 99.90 | 0.04 | 0.03 | 0.001 | 0.004 | 0.02 | 0.03 | — | — | — | 一 | 0.01 |

| Mg9980 | 99.80 | 0.05 | 0.05 | 0.002 | 0.02 | 0.05 | 0.05 | — | — | — | 0.05 | |

| Cd、Hg、As , Cr6+, ω( Cd + Hg + As +Cr6+ )≤0.03% | ||||||||||||

Ps: chemical compostion and size above can be optimized according to custom's requirement.

25Kg/bag, 1MT/bag or according to customer's requirements

1.100% EXW Price

2.100% irrevocable L/C at sight

3.30% advance payment, Balance against copy B/L.

Within 10 days after receiving the prepayment.

Henan Tiesheng Alloy New Material is a professinal ferroalloys manufacturer. The main products are Nodulizer,Inoculant, Ferro Silicon, Calcium Silicon, Spheroidizing Wire, Magnesium Ingot, Recarburizer, Silicon Carbide, Silicon Metal, etc.

Magnesium Ingot is one of the ferroalloys commonly used in steel industry. Products are exported to Malaysia, the Philippines, Singapore, South Korea, Japan and Europe and the United States and other countries and regions. The quality of lc ferro chromium products is stable and the price is low. It is well received by customers.

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.