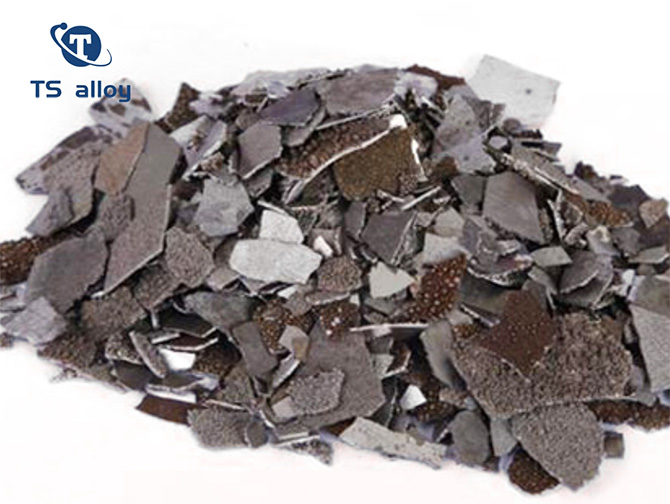

Electrolytic Manganese Metal Flakes is widely used as deoxidizing agent, desulfurizing agent, and alloying agent in the steel industry. There are four forms of manganese metal: manganese metal flakes, manganese metal lumps, manganese metal briquette, and manganese metal powder.Our company adopts electrolytic melting method to produce manganese,which has the more higher content of Mn, lower content of CS and other elements, with the use of a wider range.

Whatsapp:

+8618337276299Email:

sale01@tsferroalloy.com(1) Manganese and manganese alloy is one of the indispensable raw materials in the iron and steel industry, aluminum alloy industry, magnetic material industry and chemical industry.

(2) Manganese Metal is an indispensable additive in smelting industry. Electrolytic metal manganese processing into powder is the main raw material for the production of manganese tetroxide.

(3) Electrolytic manganese metal due to its high purity, low impurity characteristics, has been successfully and widely used in iron and steel smelting, non-ferrous metallurgy, electronic technology, chemical industry, environmental protection, food hygiene, electrode industry, aerospace industry and other fields.

(4) The purity of electrolytic manganese is very high, its role is to increase the hardness of metal materials, the most widely used in manganese copper alloy, manganese aluminum alloy, 200 series stainless steel. Manganese in these alloys can improve the strength, toughness, wear resistance and corrosion resistance of the alloy.

Electrolytic Manganese Metal Flakes is widely used as deoxidizing agent, desulfurizing agent, and alloying agent in the steel industry. There are four forms of manganese metal: manganese metal flakes, manganese metal lumps, manganese metal briquette, and manganese metal powder.Our company adopts electrolytic melting method to produce manganese,which has the more higher content of Mn, lower content of CS and other elements, with the use of a wider range.

Our electrolytic manganese boasts extraordinary purity, enhancing the hardness of various metal materials. It is predominantly utilized in the creation of durable manganese-copper alloys, lightweight manganese-aluminum alloys, and robust 200 series stainless steels.

Within these advanced alloys, manganese plays a crucial role by augmenting their strength, enhancing toughness, and significantly boosting wear and corrosion resistance, ensuring longevity and resilience.

In step with technological advancements and heightened productivity demands, electrolytic metal manganese has become indispensable across numerous fields. Its high purity and minimal impurities make it a preferred choice for iron and steel smelting, non-ferrous metallurgy, electronic technology, and chemical industry. Additionally, it serves a vital role in environmental protection, food safety, welding electrodes, aerospace ventures, and more.

|

NO LESS(%) |

NO MORE(%) |

|||

|

Mn |

C |

Si |

P |

S |

|

99.7 |

0.04 |

0.01 |

0.01 |

0.03 |

Ps: chemical compostion and size above can be optimized according to custom's requirement.

25Kg/bag, 1MT/bag or according to customer's requirements

1.100% EXW Price

2.100% irrevocable L/C at sight

3.30% advance payment, Balance against copy B/L.

Within 10 days after receiving the prepayment.

Henan Tiesheng Alloy New Material is a professinal ferroalloys manufacturer. The main products are Nodulizer,Inoculant, Ferro Silicon, Calcium Silicon, Spheroidizing Wire, Magnesium Ingot, Recarburizer, Silicon Carbide, Silicon Metal, etc.

Electrolytic Manganese Flake is one of the ferroalloys commonly used in steel industry. Products are exported to Malaysia, the Philippines, Singapore, South Korea, Japan and Europe and the United States and other countries and regions. The quality of lc ferro chromium products is stable and the price is low. It is well received by customers.

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.